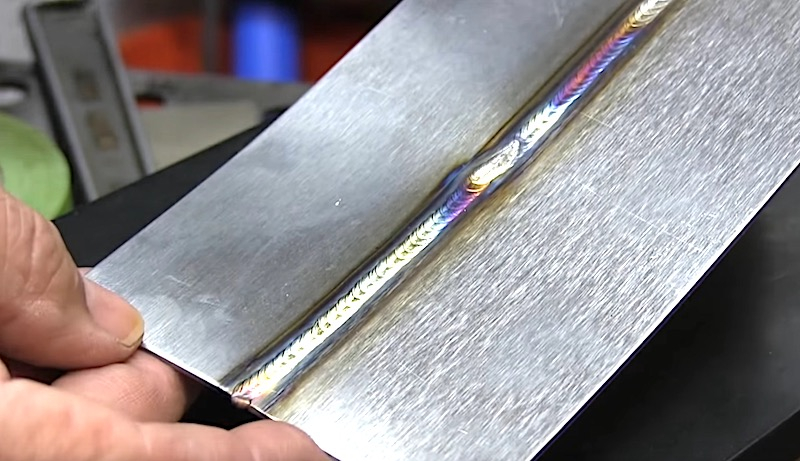

When it comes to welding stainless steel, understanding the weld color chart is essential for achieving the desired results. The color of the weld can provide valuable information about the welding process, including the temperature, oxidation level, and potential issues that may arise. By familiarizing yourself with the stainless weld color chart, you can improve the quality of your welds and ensure the longevity of the finished product.

The colors that appear on a stainless weld are a result of the oxidation process that occurs during welding. Each color corresponds to a specific temperature range, with lower temperatures producing lighter colors and higher temperatures resulting in darker colors. For example, a straw color indicates a temperature range of around 450-600°C, while a blue color signifies temperatures of 600-900°C. By monitoring the color of the weld, welders can adjust their techniques to achieve the desired results.

Stainless Weld Color Chart

Common Issues and Solutions

One common issue that welders may encounter when using a stainless weld color chart is overheating, which can result in discoloration or even structural damage to the metal. To prevent overheating, it is important to control the heat input and maintain proper shielding gas coverage. Additionally, improper cleaning of the metal surface can lead to contamination and affect the color of the weld. By following best practices and regularly referencing the stainless weld color chart, welders can avoid these issues and produce high-quality welds.

Download Stainless Weld Color Chart

Stainless Steel Weld Color Chart

Stainless Steel Weld Color Chart

Acceptable Stainless Steel Weld Color Chart Infoupdate

Acceptable Stainless Steel Weld Color Chart Infoupdate